23andMe CEO joins $45M funding for women’s health tech startup

February 20, 20202020 will see a shift away from the culture of personality at startups

February 27, 2020By Verne Harnish

Southland Trailer Corp. finished last year with $37 million in annual revenue—up from about $15 million four years ago—and saw a 50% increase in net income. That is despite tariffs that resulted in higher steel pricing, affecting the margins on the cargo trailers, flatbeds and other trailers it sells.

The Alberta, Canada-based company pulled it off by using the Scaling Up system for growing a company, in conjunction with the Lean methodology described in The Toyota Way, to improve its processes.

“I’ve read Scaling Up or listened to the audio version five or six times,” says Ryan Sailer, Southland’s general manager, whose father founded the company. “We’ve referenced it a ton. We try to get the best fit with the Lean side of how we are doing business.”

Speeding the cash conversion cycle

One key step to the company’s results was tracking the cash conversion cycle (CCC), the time it takes from the point someone places an order to the date when the company is paid by its customers. The company relied heavily on the Cash Acceleration Strategies from Scaling Up: Rockefeller Habits 2.0.

Southland, which has more than 100 employees, looked into details like how easy it is for customers to order and how easy it is for them to pay. Then it incorporated what it wanted to improve on into its Quarterly Themes and rocks to improve cash flow. “We dissected it: Did we nail it or do we need to continue working on it?” says Sailer.

Within about 15 months, the average cash conversion cycle shrunk from 135 to 45 days. “It is still improving on a monthly basis as we improve our internal manufacturing and receivables process,” he says.

Fine-tuning production

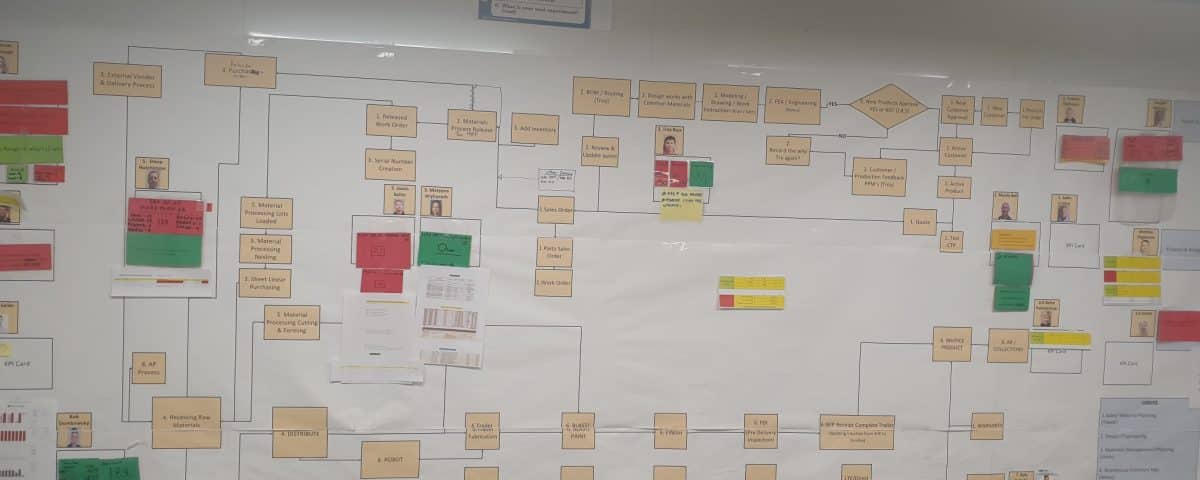

Southland Trailer also created a “process map,” visible in a place the whole team can view, to uncover inefficiencies in its processes. The map looks at sales, design and engineering, scheduling, purchasing and other activities. “In 10 seconds or less, we can decipher the performance of the company over the past week,” says Sailer.

To create the map, the company drew on both the Function Accountability Chart (FACe) and Process Accountability (PACe) tools from Scaling Up, as well as elements of the Lean system.

Each item listed on the map has a key performance indicator (KPI), or metric assigned to it, with weekly targets. For instance, for sales, the company measures the backlog of upcoming orders. The chart is color-coded, with green, yellow and red, to indicate how well the company is doing. “If there are any below the target, we want to go to red,” says Sailer.

Next to each step on the map is the picture of an accountable individual. “We believe in candor,” says Sailor. “If we see an issue, we ask, ‘Why are we seeing it? What are you doing about it? How do we get other departments involved to solve the issue?’”

The team might address a problem like a decline in orders from dealers by offering promotional pricing.

Team-specific huddle boards

Southland has created specific “huddle boards” for internal teams, like sales and production, that track micro-level KPIs. These are inspired by the PACe and FACe.

“They wouldn’t be relevant for everyone else to see in the weekly meetings,” says Sailer.

Quarterly Themes

Southland has also introduced Quarterly Themes, to get everyone in the company rowing in the same direction. For the quarter ending in March 2020, the theme is “Continuous improvement,” with a goal of 1,500 improvements by that date. “We post these all over the company,” says Sailer.

These efforts to combine the Scaling Up system with Lean manufacturing are paying off: The 40-year-old, family-run firm has positioned itself for fast growth, to the point that it hired 50 people in the past year and was able to purchase an additional warehouse of about 130,000 square feet about a year ago.

“It’s been a winning combination,” says Sailer.